Update to OSHA's PSM Regulation: Part 5: Oil and Gas-Well Drilling

The material in this post has been incorporated into the book The OSHA Process Safety Standard: The 30-Year Update.)

The United States Occupational and Health Administration (OSHA) is proposing to update its Process Safety Management (PSM) standard. This post is the fifth in a series in which we discuss some of the proposed changes. OSHA’s proposal document is Process Safety Management (PSM): Stakeholder Meeting. The item we consider in this post is:

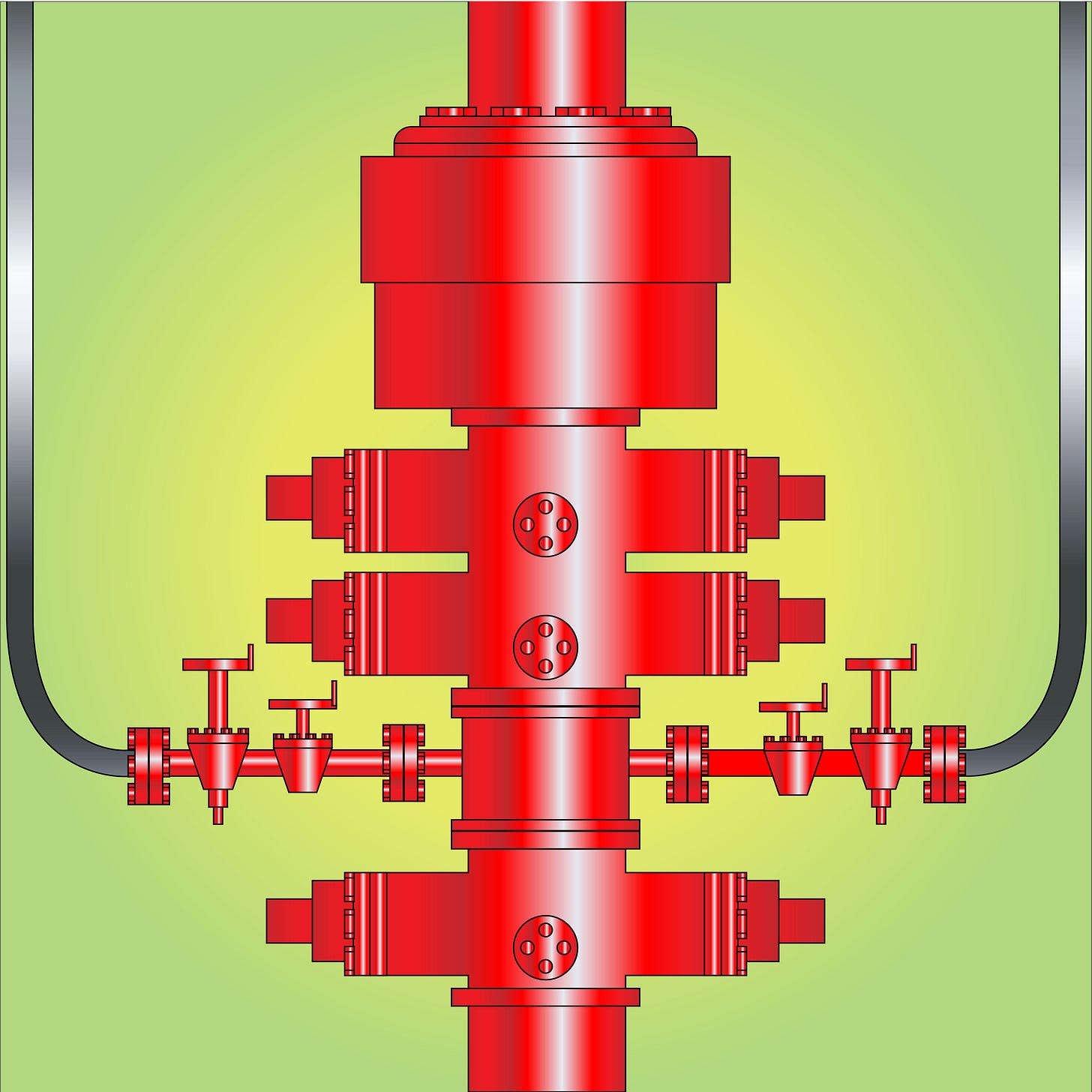

II. 2. Expanding the scope to include oil-and gas-well drilling and servicing.

Three Options

Background to this item is provided by the Chemical Safety Board (CSB) and their investigation of the Pryor Trust Fatal Gas Well Blowout and Fire. The CSB issued nineteen recommendations, one of which was directed to OSHA. That recommendation reads,

Implement one of the three following options regarding regulatory changes:

(a) OPTION 1: Apply the Process Safety Management (PSM) standard (29 CFR 1910.119) to the drilling of oil and gas wells; or

(b) OPTION 2: Apply the Process Safety Management (PSM) standard (29 CFR 1910.119) to the drilling of oil and gas wells as in OPTION 1, and make the necessary modifications to customize it to oil and gas drilling operations; or

(c) OPTION 3: Develop a new standard with a safety management system framework similar to PSM that applies only to the drilling of onshore oil and gas wells that includes but is not limited to the following:

1. Detailed written operating procedures with specified steps and equipment alignment for all operations;

2. Written procedures for the management of changes (except replacements in kind) in procedures, the well plan, and equipment;

3. A risk assessment of hazards associated with the drilling plan;

4. A requirement to follow Recognized and Generally Accepted Good Engineering Practices (RAGAGEP);

5. Development of a Well Construction Interface Document between the operator and the drilling contractor prior to the commencement of drilling activities which at a minimum includes a bridging document and well plan specifying barriers and how to manage them;

6. The performance and documentation of flow checks using acceptable methods at defined points during the operation for a specified duration; and

7. A requirement for employee participation, similar to the Employee Participation requirement in the OSHA PSM standard.

Drilling not Steady-State

OSHA’s process safety standard has its roots in the chemical industry.

Keep reading with a 7-day free trial

Subscribe to Net Zero by 2050 to keep reading this post and get 7 days of free access to the full post archives.