The Process Safety Professional. Process Safety Fundamentals (Part 4)

We are working on the book The Process Safety Professional. The current Table of Contents is available here. We are gradually releasing the contents of the book to paid subscribers. This is the fourth release. The topic is ‘Acceptable Risk’.

Acceptable Risk

In spite of the difficulties just described, it is still necessary to have a clear understanding as to what levels of risk are acceptable. After all, if a facility operates for long enough, it is certain - statistically speaking - that there will be an accident. Therefore, process safety professionals need guidance as to what level of “acceptable safety” is required. This is tricky. Regulatory agencies in particular will never place a numerical value on human life and suffering because any number that they propose would inevitably generate controversy. Yet working targets have to be provided, otherwise the facility personnel do not know what they are shooting for. Nor can a regulatory body, a professional society or the author of a book such as this can provide an objective value for risk.

Individuals and organizations are constantly gauging the level of risk that they face in their personal and work lives, and then acting on their assessment of that risk. For example, at a personal level, an individual has to make a judgment as to whether it is safe or not to cross a busy road. And there is the further complication of the subjectivity of risk. Someone who is strongly opposed to having a chemical plant near their home may happily choose to go bungee jumping at weekends.

In an industrial context managers make risk-based decisions regarding issues such as whether to shut down an equipment item for maintenance or to keep it running for another week. Other risk-based decisions made by managers are whether or not an operator needs additional training, whether to install an additional safety shower in a hazardous area, and whether a full Hazard and Operability Analysis (HAZOP) is needed to review a proposed change. Engineering standards, and other professional documents, can provide guidance. But, at the end of the day, the manager has a risk-based decision to make. That decision implies that some estimate of “acceptable risk” has been made.

One company provided the criteria shown for its design personnel. The values are for fatalities per year (employees and contractors).

• Intolerable risk >5 x 10-4

• High risk <5 x 10-4 and >1 x 10-6

• Broadly tolerable risk <1 x 10-6

Their instructions were that risk must never be in the 'intolerable' range. High risk scenarios are "tolerable", but every effort must be made to reduce the risk level, i.e., to the "broadly tolerable" level.

One of the biggest challenges that process safety professionals face is deciding on what level of risk is acceptable within a given context. The professional’s manager or client is likely to eventually say something on the following lines,

“You have identified a problem or hazard. Is the associated risk so high that I am forced to take action? What is your recommendation?”

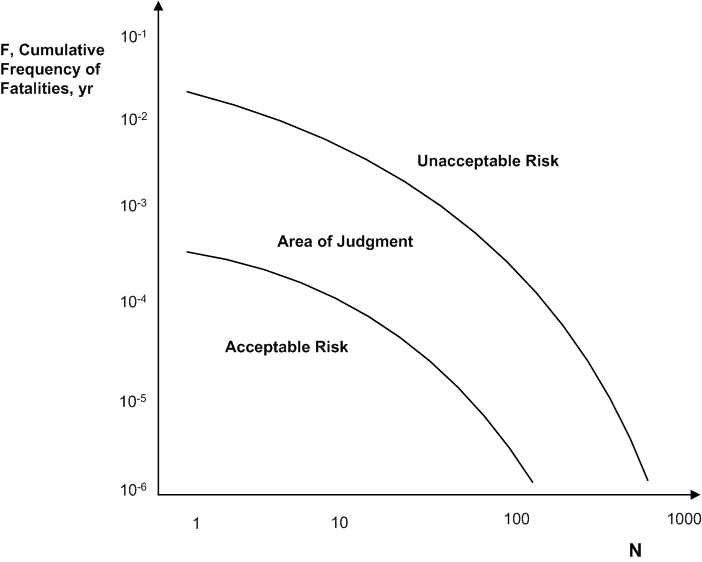

As Low as Reasonably Practical — ALARP

Some risk analysts use the term 'As Low as Reasonably Practical (ALARP)' for setting a value for acceptable risk. The basic idea behind this concept is that risk should be reduced to a level that is as low as possible without requiring “excessive” investment. Boundaries of risk that are definitely acceptable or definitely not acceptable are established as shown in the chart, which is an FN curve family. Between those boundaries, a balance between risk and benefit must be established. If a facility proposes to take a high level of risk, then the resulting benefit must be very high.

Figure 2.3

F-N Curve: Levels of Risk

Risk matrices can be used to set the boundaries of acceptable and unacceptable risk. The middle squares in such a matrix represent the risk levels that are marginally acceptable.

One panel has developed the following guidance for determining the meaning of the term As Low as Reasonably Practical.

Use of best available technology capable of being installed, operated and maintained in the work environment by the people prepared to work in that environment;

Use of the best operations and maintenance management systems relevant to safety;

Maintenance of the equipment and management systems to a high standard;

Exposure of employees to a low level of risk.

The fundamental difficulty with the concept of ALARP

Keep reading with a 7-day free trial

Subscribe to Net Zero by 2050 to keep reading this post and get 7 days of free access to the full post archives.