If we are to properly address the climate crisis, we need to understand that climate change is a symptom of a larger set of integrated problems and predicaments. In other words, systems thinking is called for.

To take a very simple example, we read that electric vehicles (EVs) have no greenhouse gas (GHG) emissions. But what we do not read about is the large quantities of fossil fuels needed to mine the lithium and other rare earth metals that are needed to manufacture the EV batteries, and then to dispose of those batteries at the end of their life. In other words, it is rare to see a full analysis of the net savings in GHG emissions (assuming that there are any). It is even rarer to consider the effect of mining for lithium on the natural environment and overall biosphere destruction.

Given this background, I found this post from Anna Marie to be useful.

Systems thinking is a holistic approach to analysis that focuses on (a) the way that a system's constituent parts interrelate, (b) how systems work over time, and (c) how systems work within the context of larger systems. This is different than small-scale analysis that focuses on one element (or one “unit operation” of a system).

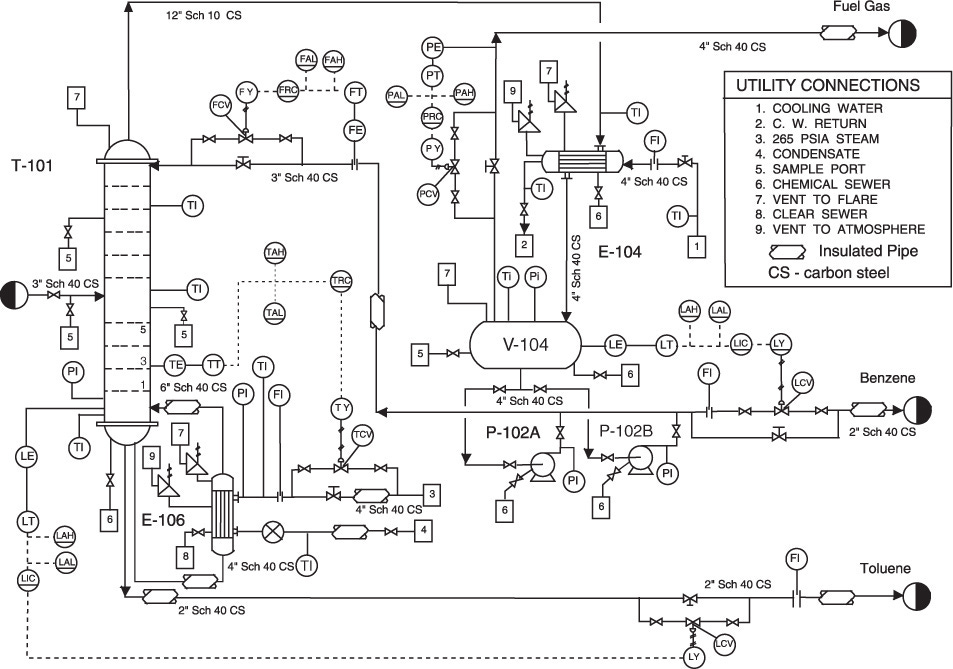

One analogy I like to use is that chemists invent chemical reactions in a lab setting (understanding how reactions work, what temperature/pressure the reactions need to be ran at, what product concentrations can be achieved with what reactant concentrations, etc.) and then they hand their work off to a chemical engineer who builds everything else around that reaction so that it can take place at production scale (upstream operations like integrated heat exchangers and pumps to make sure the reactants and reactor are at the right temperature and pressure, or downstream operations like distillation columns to purify the product, etc.)

Translation: it means we understand shit like this…

When you’re trained in chemical engineering, it doesn’t just mean you’re trained in (for example) “how distillation columns work”. It means you’re trained in understanding how each input and output of the distillation column interacts with each input and output of every operation around it; the reboilers, the pumps, the other separators downstream, the feed stream, and the associated temperatures, pressures, flow rates, and concentrations of each material in each stream. It’s complex!!

Even Greater Complexity

The above discussion has not fully captured the complexity of a modern process plant. The next sketch shows a very, very highly simplified iconic flow diagram of a mid-sized refinery.

Each of the major blocks in that sketch incorporate multiple engineering drawings of the type that we have just seen.

Complex and Complicated

It is important to distinguish between complicated and complex problems. A complicated problem is rule based, comprehensible, predictable and controllable. For example, if a car will not start it is possible to use a checklist or maintenance manual to find out what is wrong, and then fix the problem. Finding the solution may be difficult, and solving it may require special tools and training, but a solution does exist.

Complexity, on the other hand, involves many interconnected parts with dynamic interactions that produce unpredictable outcomes. These systems are adaptive and emergent, meaning they evolve over time in response to internal and external changes. There are no solutions to complex problems ― only responses.

Climate change is complex; it is affected by many parameters and variables, all of which affect one another in ways that are difficult to understand, or even to identify. This complexity means that we need to be very cautious about proposing simple solutions to the dilemmas that we face.

Chemical Engineering

Chemical engineers are typically well-equipped to understand and solve complex problems. Their training includes a broad foundation in mathematics, physics, chemistry, and engineering principles, which they apply to design, analyze, and optimize processes. They combine knowledge from various fields, enabling them to tackle problems that intersect multiple disciplines. This diverse skill set allows them to adapt to new challenges in various industries, from energy to pharmaceuticals.

CC&S

One specific area that will require chemical engineering skills is Carbon Capture and Sequestration (CC&S). There are many reasons to be cautious about this technology, but it is likely that more and more companies will invest in it, and therefore they will call on chemical engineers to develop, design, install, operate and maintain CC&S facilities.