BSEE Safety Alert No. 465. Improper Use and Application of High-Pressure Hoses

Management of Change / Culture

March 8, 2023

BSEE (the United States Bureau of Safety and Environmental Enforcement) issues regular ‘Safety Alerts’ to do with offshore safety. These Alerts are usually based on incidents or near misses. Alert No. 465 is Improper Use and Application of High-Pressure Hoses Can Cause Injuries. These Alerts tend to focus on occupational safety issues. In this example, the agency has put forward multiple recommendations regarding the safe use of hoses.

In addition to the direct lessons learned, these Safety Alerts can also provide guidance and insights to do with process safety management. (The BSEE process safety standard is known as SEMS — the Safety and Environmental Management System.) In this case, a cause of the near miss is actually failure to apply the principles of Management of Change (MOC).

MOC is usually thought of as a formal and structured process for identifying and controlling proposed change to a system. Someone proposes a change, that proposal is entered into the system (often using specialized software), a team evaluates the proposal (frequently using process hazards analysis), and authorization is then given (or not given) for the change to be made.

Yet, like all other aspects of process safety, Management of Change is basically a way of thinking — all personnel should be looking at what they are doing and asking themselves, “Does what I am about to do change the system in some way, or is it a normal operation?”

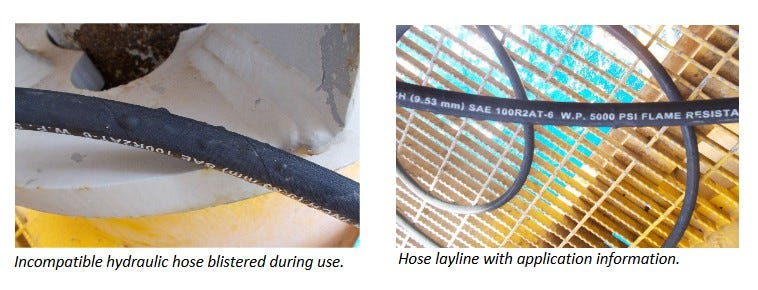

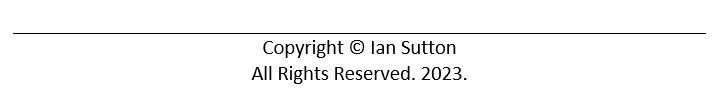

In the case of this Safety Alert, if the workers involved had asked that question they would have said, “This hose is meant for hydraulic service, but I am using high pressure nitrogen. Therefore, I have made a ‘Change’. Before going ahead, I need to check with my supervisor.”

The elements of SEMS are,

General

Safety and Environmental Information

Hazards Analysis / Job Safety Analysis

Management of Change

Operating Procedures

Safe Work Practices

Training

Assurance of Quality and Mechanical Integrity of Equipment

Pre-Startup Review

Emergency Response and Control

Investigation of Incidents

Audit of Safety and Environmental Management Program Elements

Records and Documentation

Stop Work Authority

Ultimate Work Authority

Employee Participation

Reporting of Unsafe Conditions

We have highlighted the Management of Change elements due to its relevance to this Safety Alert. But we have also highlighted Employee Participation because it is equally relevant to this incident. (Other process safety standards use the word ‘culture’ in this context.)