BSEE Safety Alert No. 459. Lack of Training Leads to Fatality.

March 8, 2023

The Bureau of Safety and Environmental Enforcement (BSEE) has issued "Safety Alert No. 459 — Lack of training with Hydraulic Torque Wrench contributes to fatality aboard drill ship." A summary of what happened is provided here. The detailed report is here.

The Incident

The Summary of the Alert reads,

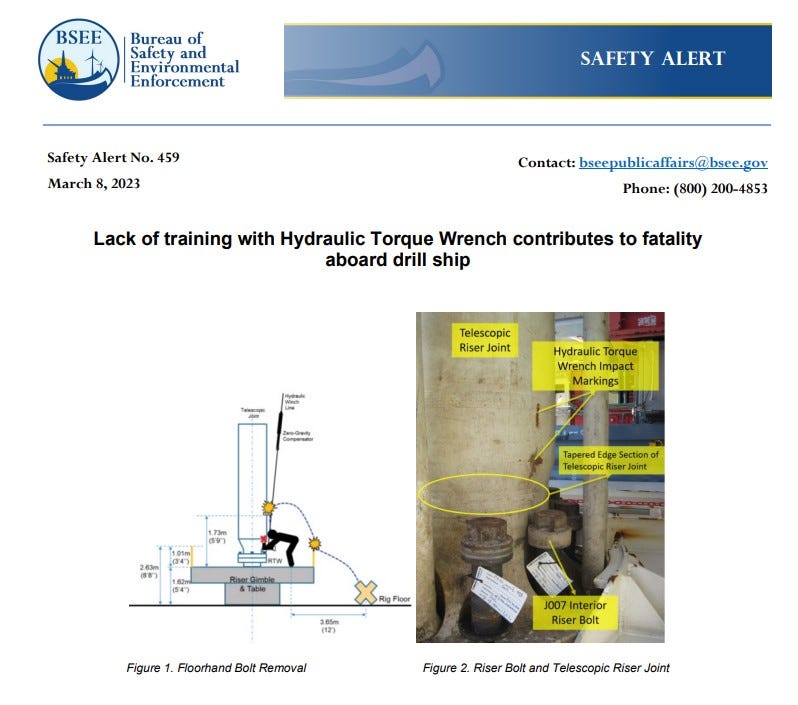

During well operations, a fatality occurred on a drillship in the Gulf of Mexico.

While unlatching the lower Marine Riser Package from the Blowout Preventor in preparation for ship relocation, a crewmember was lifted into the air after being struck by a hydraulic torque wrench (HTW), hitting a riser clamp approximately six feet above the elevated work deck before falling to the rig floor. The crewmember was given first aid and transported to the drillship’s hospital, where he was later pronounced deceased.

Contributing Factors included the following:

Lack of recognizing the stuck-HTW potential on the TJ beveled edge.

Lack of comprehensive understanding of the Task Risk Assessments associated with the riser pull.

Failure to effectively communicate all learnings from the previous riser pulls.

Lack of formalized training for the utilization of the HTW and HUW.

Adverse designs of the HTW and the HUW.

Contributing Causes:

Failure to initiate Stop Work Authority.

Discrepancies with the Drill Floor Observer roles and responsibilities.

Therefore, BSEE recommends that operators and contractors consider the following:

Ensure the Job Safety Analysis captures the limitations of the HTW when in use.

Verify all employees understand the Job Safety Analysis and have been formally trained on operating both the HTW and HUW.

Emphasize the initiation of Stop Work Authority if an imminent danger is observed.

Expand the Drill Floor Observer responsibilities to monitor all aspects of jobs occurring on the rig floor.

Consider utilizing a HTW with a compatible design that corresponds with the beveled edge of the TJ.

Explore options for employing a load indicator, or a similar design mechanism onto the HUW package.

Ensure pre-job reviews, promote the sharing of feedback from previous experiences.

Discussion

BSEE attributes the causes of the incident to inadequate training, lack of communication with regard to the Job Safety Analysis (JSA), and failure to use Stop Work Authority.

Training

The topic of training is discussed in our ebook on the topic. BSEE argues that, if the technician had been better trained, he would have been aware of the dangers associated with hydraulic torque wrenches.

Job Safety Analysis

We are not told about the JSAs that may have been carried out at the start of the assignment. If a JSA was conducted, it clearly did not identify the risks to do with hydraulic torque wrenches.

Stop Work Authority

If the technician had decided to stop the task when he first ran into difficulties, and then asked for support, the incident may not have occurred. (In our discussions to do with the proposed updates to the OSHA process safety standard we discuss the best use of Stop Work Authority, and also the times when stopping work could actually increase the risk of an accident.) We also discuss another BSEE Safety Alert that involved Stop Work Authority.